Automation and Digitalization: a winning combination

In 2025, industrial equipment suppliers are expected to excel in automation, foster the adoption of collaborative robots, and guide industries toward smart factory transformations.

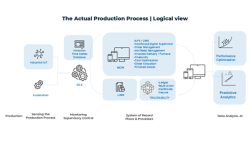

EPIQ Machinery, aligned with its mission, has strengthened its leadership by integrating two new subsidiaries, EPIQ Digital and NOVIMEQ Automation , to enhance its position in the Industrial Internet of Things (IIoT) sector. This empowers EPIQ to deliver equipment and solutions within a digital ecosystem that leverages edge computing and real-time analytics, addressing the evolving demands of industries such as aluminum production.

IT and OT Convergence: Opportunities and Challenges

As Rishabh Kaushik, Managing Director of NOVIMEQ Automation pointed out in a recent article: the convergence of Information Technologies (IT) and Operation Technologies (OT) is unavoidable. While it unlocks incredible opportunities, it requires an intensified emphasis on cybersecurity.

Most OT networks were not designed with cybersecurity in mind. Factories evolve over decades; new machinery is added and outdated systems are repaired.

As we connect OT systems with IT networks to drive efficiency and gather data, these systems become more vulnerable. What was once an isolated equipment is now integrated into a digital ecosystem. This convergence is potent, yet it also introduces cybersecurity concerns that can disrupt production, compromise safety, and diminish revenue.

Also, as producers are seeking to modernize their industrial equipment and systems, accurately forecasting the behavior of each piece of equipment might prove to be difficult. This is why digital twin solutions are advantageous.

Digital twins or virtual commissioning simulates a physical system. It enables engineers to model its functionality in real-world scenarios. The digital twin allows teams to test, evaluate and refine systems in a safe virtual environment before any physical equipment is involved.

It highlights prospective difficulties that can be recognized and resolved digitally, hence reducing the possibility of expensive errors during actual deployment. This minimizes the likelihood of downtime and maintains project timelines, rendering the procedure both expedited and more cost-effective.

In the world of industrial automation, efficiency and precision are essential for staying competitive. NOVIMEQ Automation’s network assessment and virtual commissioning services allow clients to optimize their systems in a cost-effective and time-saving manner.

EPIQ Digital: Driving Industrial Transformation

With over 30 years of expertise, EPIQ Digital develops and implements advanced industrial IT solutions.

Its Manufacturing Operations Management (MOM) platform is specifically tailored for aluminum primary and secondary production smelters. Currently, it is monitoring approximately 2 million metric tons of aluminum annually, the platform offers unparalleled capabilities.

Oriented to the systems and software, it brings legacy and new systems cohesively together. The platform encompasses a core framework that connects both existing and future modules to maintain a unified operational ecosystem. It includes generic modules that provide essential functionalities common across various operations, hybrid modules, and specific modules tailored to meet the distinct needs of individual customers in the aluminum smelting sector.

It offers a modular and scalable solution that integrates seamlessly into current operations, addressing both the general requirements of aluminum producers and the intricacies of their processes.

It not only enhances operational efficiency but also fosters innovation, enabling aluminum production smelters to improve performance, achieve decarbonization objectives, and expedite the transition to autonomous production facilities.

With the expansion of the global installed base of adaptive robots, the volume of generated data is substantial. While embedding other features such as artificial intelligence (AI) or machine learning (ML) capabilities, infrastructure requires a robust and dependable digital environment for data computation and analysis.

This advanced platform supports a wide array of technologies, including autonomous mobile robots (AMRs) and autonomous guided vehicles (AGVs), Industrial IoT, edge computing, and AI-driven agents, ensuring that our clients stay at the front of technological progress.

At EPIQ, we transform material handling processes, boosts productivity, and spearheads digital transformation by fully harnessing the potential of industrial automation and digitalization. Through innovative software solutions designed by EPIQ Digital’s, the group offers Cutting-Edge Technologies.

Key Features of the MOM Platform

- Enhanced Robotics and Automation: Facilitates real-time data collection and analysis, supporting operational adjustments and integration of AMRs and AGVs.

- Robust Digital Infrastructure: Ensures reliable, low-latency communication for AI-driven decision-making and consistent operational performance.

- Modular Design: Reduces capital (CAPEX) and operational (OPEX) expenditures while accommodating the complexities of aluminum smelting processes.

- Sustainability and Efficiency: Improves productivity, reduces energy consumption, and promotes decarbonization goals.

INNEXUS Platform: A Benchmark for Aluminum Producers

The INNEXUS digital platform, the fourth generation, is designed to monitor, manage and optimize manufacturing processes for aluminum producers.

Our smart manufacturing solutions offer insights, facilitate optimal asset usage, enhance productivity, ensure regulated and predictable outcomes, and lead to a culture of continuous improvement.

At a functional level, INNEXUS comprehensively covers all production sectors within the aluminum industry, including potline integration, carbon plant, casthouse, GTC, port, and more.

It also tackles nontraditional challenges in the Aluminum Industry through Advanced Planning and Scheduling, Condition Monitoring, Anodes Distribution, Crucible Tracking, and Advanced Hot Metal Management, among others.

Core Functionalities

- Integration of all production sectors, including potline, carbon plant, casthouse, and port operations.

- Advanced planning and scheduling, condition monitoring, and equipment traceability.

- Seamless connectivity with enterprise systems (ERP, historian, LIMS) to ensure data cohesion and operational efficiency.

Technological Advancements

- Utilization of edge/fog computing and MQTT protocols for efficient machine-to-system communication.

- Advanced KPIs and real-time analytics for comprehensive performance oversight.

Automation and Digitalization: A Strategic Imperative

Nowadays, modern industrial solutions must be scalable, adaptable, and seamlessly integrated with legacy systems. EPIQ’s approach addresses these challenges, ensuring compatibility, eliminating data silos, and minimizing operational disruptions.

In other words, adding automation and digitalization leads to rethinking and re-evaluating processes. So, what you can expect from an industrial equipment supplier is to offer strategic insights into digital transformation, ensuring clients stay ahead in a competitive and rapidly evolving landscape. This is EPIQ.

About the author

Isabelle Gaudreau manages Marketing and Communication for EPIQ Machinery. She looks at all aspects of marketing-related activities. She started in the industry in 2006 while assisting in sales, marketing, promotional materials, and general activities.

Her background in professional writing, creative design work, and administrative services offers a balanced mix between having insights into the industry and being an observer of new trends and opportunities.